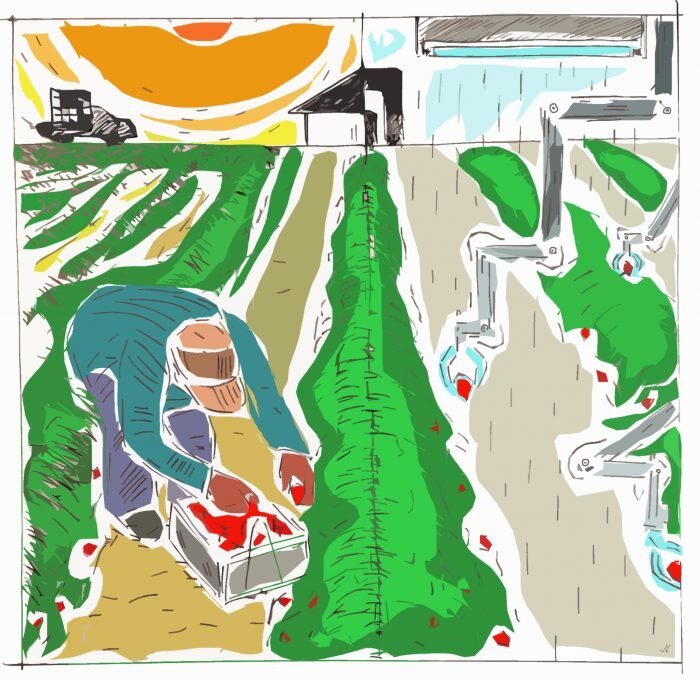

It’s a misty morning near Salinas, California and the advanced.farm TX harvester—a lightweight, driverless tractor covered in canvas—is picking strawberries. Like a dot-matrix printer moving along a page, the harvester’s robotic hands move back and forth along the beds, scanning for signs of red. When it identifies a ripe berry, it dives down, gently plucks it from the plant, and places it in a crate.

At the same time, a crew of about two dozen farmworkers is also harvesting strawberries just a few hundred feet away, on an adjacent farm. As an energetic song blasts from a parked vehicle, the men and women stoop to pick berries straight into plastic clamshells that they tile, side-by-side, into cardboard trays. Once their trays are full, the workers take them back to one of several sorting tables spread out along the access road (to allow for social distancing). It’s clear by the speed at which they’re walking—and in some cases even running—to drop off each box that these men and women are getting paid by the piece.

I’ve trudged through the muddy, irrigated fields to watch both forms of harvest with Kyle Cobb, advanced.farm’s youthful, clean-cut CEO. The company was the first to mechanically harvest strawberries for commercial sales last year, and had raised just under $10 million by June 2020, including a $7.5 million Series A round in 2019. After building a robot that cleaned solar panels, Cobb and his team dove into agriculture, where they hope to put an end to the notoriously grueling, repetitive work of harvesting strawberries.

If things go as planned, and advanced.farm is able to scale up over the next several years, Cobb says, “You’d see the same crew, but instead of it being this big, you’d see about half the size . . . and they wouldn’t be doing the traditional picking like this. They’d be doing a combination of sorting and packing in a very comfortable ergonomic set up.”

Read more on Civil Eats.